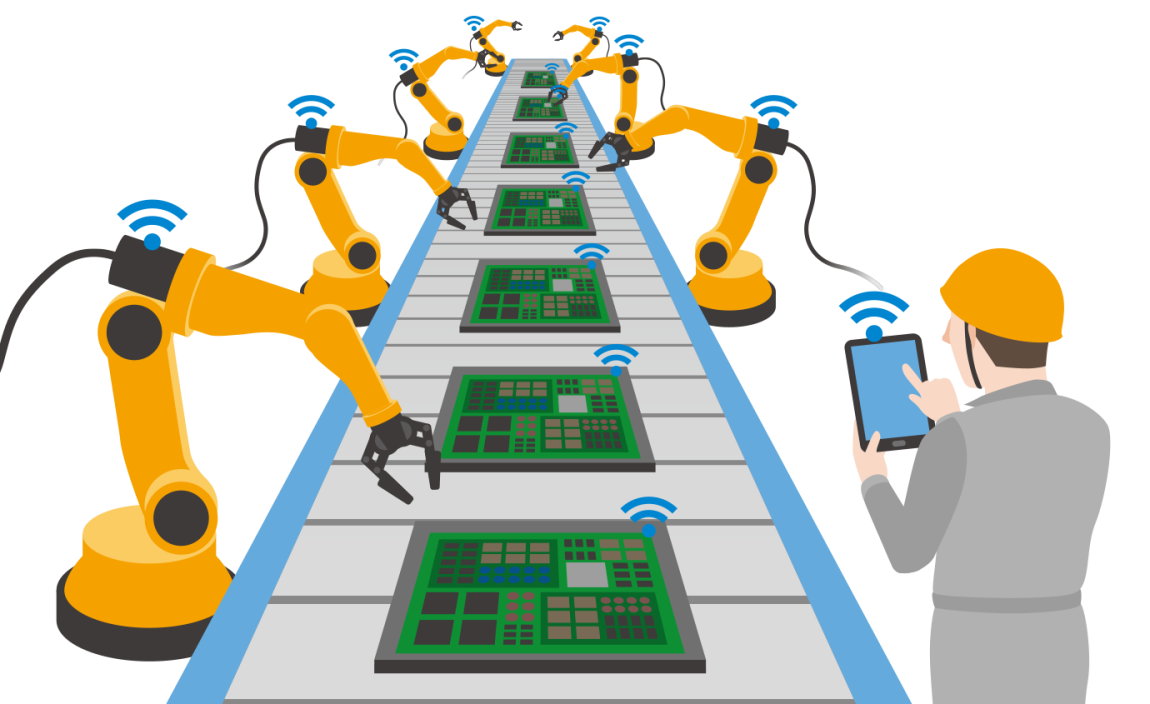

Industry 4.0

Industrial Revolution & Smart Manufacturing.

Every company and organization operating today is different, they all face a common challenge?the need for connectedness and access to real-time insights across processes, partners, products, and people. Physical production and operations with smart digital technology, machine learning, and big data to create a more holistic and better connected ecosystem for companies that focus on manufacturing and supply chain management. Businesses and supply chains already use some of these advanced technologies, but the full potential of Industry 4.0 comes to life when they're used together.

CONTACT US NOW

Digital connectivity

and sensors

the opportunities are to improve productivity, quality and efficiency and better manage risk through integration and automation, IoT solutions, AI, cloud and advanced analytics.

Digital

engineering

This full digital engineering process, including increasingly intelligent automation and blockchain-based smart contracts, can all come into play.

Digital

operations

Differentiation isn?t just about demarcating a company from rivals but can also develop whole new markets, services and business models.

Advantages of Industry 4.0

Here are the industry 4.0 benefits in manufacturing and factory digitalization benefits!

Improved Efficiency And Productivity

One of the main benefits of industry 4.0 is improved efficiency and productivity. Those will improve in multiple areas of the business, from the production line up to the product design and engineering.

Improved Knowledge Sharing And Collaboration

Any person, machine, or software will be able to easily access and share the needed information where needed, when needed, and with whoever needs it in real-time.

Improved Decision-Making

Better decisions can be taken when who is making the choice has access to all the relevant data and information. This is true for both, humans and machines.

Customer Experience

Industry 4.0 provides comprehensive information and responsiveness available to manufacturers, thus allowing them to serve their customers better.

Reduced Costs

You will achieve lower operating costs overall through better uses of resources, less wastage, reduced quality issues, and less downtime. Despite a large initial investment, you will have significantly higher profit margins to enable you to get an ROI within a few years.

Quality Assurance

Industry 4.0 gives you the capability to perfect product quality. You will also be able to assure excellence beyond the factory through product tracking during delivery. By eliminating that elusive 1% or so of defective products, you can also keep your costs to a minimum.

Industry 4.0 is characterized by the addition of disruptive technologies and methods.

Aspects of Industry 4.0 have a significant impact on marketing, and have led to an evolution to ensure that marketing activities align with technological advancements and address consumers? current needs.